Product Video

Product Introduction

Product Description

Poly Tetra fluoroethylene, short for PTFE, is a polymer prepared with polytetrafluoroethylene as a monomer. White waxy, translucent, good heat and cold resistance, can be used at -180 ~ 260ºC for a long time. This material has acid and alkali resistance, resistance to various organic solvents, and is almost insoluble in all solvents. At the same time, PTFE has the characteristics of high-temperature resistance, its friction coefficient is very low.

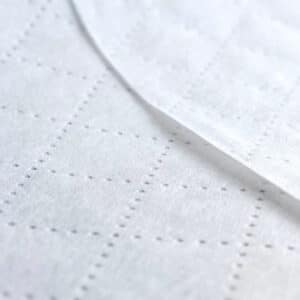

PTFE nano-aperture air filter membrane is PTFE as raw material, using PTFE film unique node fibril, smooth surface, chemical resistance, permeability, permeability, flame retardant, high-temperature resistance, strong acid and alkali resistance, non-toxic characteristics, etc. After baking, extrusion, calendering, bidirectional stretching, and heat setting, it forms a film product consisting of millions of continuous interconnected filaments with a non-concentric cross arrangement structure.

The internal structure of PTFE nano-pore membrane prepared by bidirectional stretching process presents node-pore staggered distribution, small and uniform pore size, high porosity (> 80%), and is a kind of multi-functional high-end material. PTFE membranes are characterized by extremely high efficiency, which can be achieved from E10-U17 levels of purification efficiency. Low air resistance, its resistance is only 1/2-1/3 of the glass fiber filter material. High chemical stability, high-temperature resistance, corrosion resistance, aging resistance, very low surface energy, low adhesion to dust, easy to blow dust. Surface filtration performance can blow back dust or water washing, long service life. The filtration efficiency of PTFE microporous air filter membrane is high, up to 99.99%, close to zero emission; Low running resistance, fast filtering speed; Long service life, and reusable, thus reducing operating costs.

PTFE nano-pore size air filter membrane categories are divided into bubble film, composite material, clothing film, air filter film, and electronic film.

In addition to the PTFE nanopore pore diameter air filter membrane, if you want to know more about different uses of air filter products raw materials, and air filter element products, please check the following links:

Low Resistance And High-Efficiency Molten Jet Material

Nanofiber Electrostatic Cotton Filter Material

4V Glass Fiber High-Efficiency Dense Pleat Air Filter For Pig Sow

High-Efficiency 4V Full Synthetic Fiber Dense Pleats Air Filter

5V Sub-High Efficiency Glass Fiber Air Filter For Pig Farm

5V Synthetic Fiber High-Efficiency Air Filter For Swine

Hog Sow Pig Farm Primary Effect Bag Air Filter Element

Swine Pig Farm Primary Effect Plate Air Filter Element

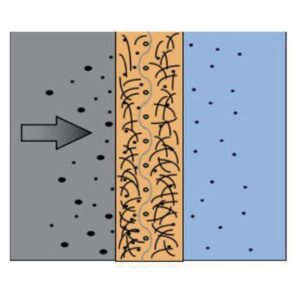

Traditional deep filtration effect

PTFE nano-pore size membrane filtration effect

Product Feature

- Surface filtration mechanism

PTFE air filter membrane has excellent surface filtration performance, the pore size of the membrane is small and uniform, and dust is not easy to penetrate the filter membrane into the base cloth when a large amount of dust is filtered, will adhere to the surface of PTFE film, forming a filter cake, after back blowing off the cake, to restore the original permeability.

- High filtering efficiency and high QF value

The pore size of the PTFE microporous membrane can be up to 0.1μm, so PTFE material can achieve very high filtration efficiency and can meet the sub-high efficiency, high efficiency, ultra-high efficiency air filter filtration efficiency level requirements. phase compared with other high-efficiency filtration materials, PTFE microporous membrane has a higher QF value and better filtration performance.

- Good uniformity and stable product performance

The uniformity of bidirectional stretch film is difficult to control, mainly including the permeability uniformity of transverse and longitudinal, but this has a great impact on the performance stability of the final device, so the raw material, process, and equipment will be reasonable design and strict control. Through the uniformity analysis of product resistance, the CV value of our membrane product can reach 7%.

- High porosity, high permeability, and high interception efficiency can be achieved simultaneously

Using the high temperature stretching process, the knot-fiber structure is regular, has high porosity, uniform pore size distribution, and the average pore size in the range of 0.1-5^m adjustable, on the one hand, the high density of fiber accumulation ensures the filtering accuracy of fine and small dust, On the other hand, high porosity and good pore size uniformity make the air permeability of the film is also excellent. The balance of high permeability and high interception efficiency makes the product very suitable for the interception and collection of fine dust. After testing the resistance and filtration efficiency, the QF value of our membrane products can reach more than 29 (0.1-02 particle size segment).

- Good membrane strength and long service life

Generally, the relative density of the standard is small (SSGW2.162), and the molecular weight is high (Mn & GT; 7 million)) and PTFE powder with narrow molecular weight distribution, the strength of the raw material is high, and the same permeability and density of the film are higher so that the performance is more reliable and longer service life.

Product Parameter

|

Filter Rating |

G | Thickness | Resistance | Filtration Efficiency | Particle Size Of Test | Width |

| g/m2 | mm | Pa | % | 卩m | ||

| U1705 | 64±5 | 0.25±0.05 | 280±30 | 99.999995 | 0.1~0.2 | 610±1

1230±1 |

| U1605 | 64±5 | 0.25±0.05 | 220±30 | 99.99995 | 0.1~0.2 | |

| U1600 | 64±5 | 0.25±0.05 | 200±30 | 99.9999 | 0.1~0.2 | |

| U1505 | 64±5 | 0.25±0.05 | 180±30 | 99.9995 | 0.1~0.2 | |

| U1500 | 64±5 | 0.25±0.05 | 165±30 | 99.999 | 0.1~0.2 | |

| H1401 | 64±5 | 0.25±0.05 | 150±30 | 99.995 | 0.1~0.2 | |

| H1403 | 64±5 | 0.25±0.05 | 135±30 | 99.995 | 0.3 | |

| H1301 | 64±5 | 0.25±0.05 | 120±30 | 99.95 | 0.1~0.2 | |

| H1303 | 64±5 | 0.25±0.05 | 105±30 | 99.95 | 0.3 |

Product Application Field

- Air purification and filtration application

PTFE microporous membrane can effectively intercept dust in the air with the highest accuracy up to H14 (99.995%), low energy consumption, and is easy to wash.

- Medical food filtration applications

The filtration precision of medical and food filtration applications is very high. PTFE bubble point filtration membrane has a high rejection rate, which can ensure the complete filtration of bacteria.

- Industrial dust removal and filtration applications

PTFE microporous filter membrane has excellent corrosion resistance, excellent thermal stability, and good mechanical properties, and is widely used in the field of industrial dust removal.

- Clothing fabric filtration application

PTFE nano-filter membrane has good hydrophobic and breathable properties, is applied in clothing fabrics, and can effectively isolate rain, sweat, and wind.

- Waterproof breathable filter application

PTFE microporous filter membrane has excellent waterproof, breathable, and sound PERMEable properties, suitable for electronic products including lamps and lanterns, blocking dust and isolating rain.

- Clean room filtration application

PTFE microporous membrane filtration accuracy can reach U15 (99.9995%), and even U17, which fully meet the requirements of a high clean workshop.

- PTFE coated HEPA filter element

PTFE nano-pore filtration membrane support material composite, high filtration efficiency, low resistance, and good strength. With good non-adhesion, it is easy to remove the dust accumulated on the surface of the material, and the service life is long.

Suitable for pleating and washing, pulse back blowing applications. A high flow environment can still maintain low-pressure drop performance.

- Fine filter for medical food

Excellent wide range of chemical applicability, biosafety, and pyrogen control. Hydrophobicity and hydrophilicity are two categories: HYDROphobicity: used for gas filtration from large to sterile, large flux, high-temperature resistance, strong acid and alkali resistance, wide chemical applicability, suitable for fermenters, carbon dioxide, nitrogen, compressed air. When used in gas filtration, it can be 100% intercepted by up to 0.02 bacteriophages, bacteria, and particles.

Hydrophilic: Used for liquid filtration to achieve asepsis, chemical applicability, strong acid, alkali resistance, and high ozone strength.

Biological safety: after a 100% integrity test, meet the HIMA bacterial closure test requirements of the United States.

- PTFE coated dust bag/filter cartridge

Excellent filtration efficiency, and excellent dust cake stripping performance. The smooth surface greatly reduces the phenomenon of pasting bags, filtering wind speed high, low energy consumption. Ultrafine dust with particle size below 1mm can be captured. High porosity: 85~93%, uniform pore size distribution, temperature range: -180~260℃. Chemical corrosion resistance (slight corrosion of molten alkali metal and F2).

- Waterproof and breathable material

Sound permeable material for mobile phones, dustproof material for lamps, waterproof and breathable fabric for clothing.

11 clean room high-efficiency filter material

The production of electronic products such as clean room high-efficiency filtration applications.

FAQ

A: No, according to customer needs.

A: The professional QC team will control the quality of the goods during all mass production, or if you wish, you can arrange a third-party inspection service. We will provide bulk samples for evaluation before shipment.

A: The sample is free, but the freight is payable. Please contact us in advance if you need samples. You can prepay shipping charges via PayPal or Western Union, and we will send samples as soon as we receive your shipping charges. Or you can provide your courier (DHL, TNT, etc.) account to us for pickup.

A: We can provide customers with full supervision of the procurement process and deliver the most satisfactory goods to them.

Accept delivery terms: FOB, CFR, CIF, EXW, CIP, DDP, express; Accept payment currencies: US dollars, Euros.

A: Yes, we do. We are a professional company in livestock farm products. We have a professional and strict quality control, we must provide you the best service for your need. Our product service department will keep in touch with customers and reply at any time.

Yes, we accept ordering samples to check quality. And mixing samples is acceptable.

A: For preparing samples, depending on the number of samples and process requirements, our preparation time is 1-7 days. International express delivery time is 3-7 days.

Related products

-

Air filtration Disinfection System Material And Products

Low Resistance And High Efficiency Molten Jet Material

-

Air filtration Disinfection System Material And Products

Nanofiber Electrostatic Cotton Filter Material

-

Air filtration Disinfection System Material And Products

5V Sub-High Efficiency Glass Fiber Air Filter For Pig Farm

-

Air filtration Disinfection System Material And Products

4V Glass Fiber High Efficiency Dense Pleat Air Filter For Pig Sow

-

Air filtration Disinfection System Material And Products

5V Synthetic Fiber High Efficiency Air Filter For Swine

-

Air filtration Disinfection System Material And Products

High-Efficiency 4V Full Synthetic Fiber Dense Pleats Air Filter

-

Air filtration Disinfection System Material And Products

Hog Sow Pig Farm Primary Effect Bag Air Filter Element

-

Air filtration Disinfection System Material And Products

Swine Pig Farm Primary Effect Plate Air Filter Element