Product Video

Product Introduction

Product Description

The main forms of bacteria and viruses in our daily life are droplets, aerosols, drinking water sources, animals, plants, etc. Microorganisms such as bacteria and viruses exist in various forms, with a wide range of existence and strong transmission ability. Endanger human health, cause national economic losses, and cause social unrest. Bacteria and viruses have a wide range of hazards and long-term damage, and effective measures need to be taken to prevent and control them. Blocking the spread of bacteria and viruses If protective non-woven fabrics are used, the network structure of the material itself is used to intercept bacteria and viruses, which may easily lead to cross-infection and secondary pollution during use. Therefore, it is very important to develop efficient and safe bactericidal and virus-killing materials. Our R&D team has jointly developed new nanofiber air purification materials, nanofiber catalytic aldehyde removal materials, and other world-leading nano-new materials. The use of free radical active oxygen sterilization and virus-killing technology. Bacteria and viruses are in contact with free-radical active oxygen materials, and active oxygen is combined with bacterial protein sulfur groups and viral protein shells to oxidize, and bacterial protein sulfur groups and viral protein shells are oxidized and their structures are destroyed. This is a material that can both filter and kill viruses. Sterilize/kill virus/filter PM2.5 and other properties in one step. The free radical type active oxygen material has the advantages of broad-spectrum sterilization, fast killing speed, and high killing efficiency, and can effectively kill Escherichia coli, Salmonella, Vibrio cholera, Shigella, influenza virus, poliovirus, Virus, norovirus, helical virus, Campylobacter jejuni, Enterococcus, Pseudomonas, Klebsiella, and other bacteria and viruses, the killing efficiency is as high as 99.99%. Its application value is mainly used in air filtration products. It is used in the preparation of air purification filter element products, which can effectively intercept and kill bacteria and viruses in the air while purifying the air.

Our company focuses on the development, production, sales, and service of nanofiber materials. Our technical research and development team comes from the academicians of the Chinese Academy of Engineering and the university professor team. Jointly developed new nanofiber air purification materials, nanofiber catalytic aldehyde removal materials, and other world-leading nano new materials, and has several exclusive patent technology, authorization, and more than 20 patents in the electric invention. Nanofiber air purification materials are mainly divided into Nanofiber Electrostatic cotton filter material. Low resistance and high-efficiency molten jet material. Nanofiber Industrial filter paper. Red stone manganese zinc matt catalytic dialdehydes sterilization materials. Low resistance and high-efficiency molten jet material.

Our air filtration materials can be widely used in industrial workshop dust removal, HVAV, clean workshop, mask making, animal husbandry pig farm breeding, etc. We also develop and produce nanopore size air filtration membranes.

Product Feature

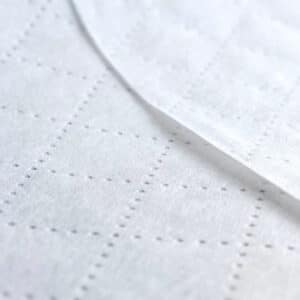

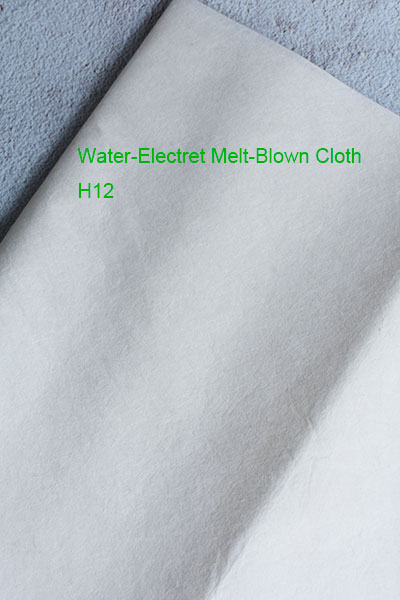

Low resistance and high efficiency melting spray material adopt professional technical team to independently develop special water electret master batch material And the technical team’s unique electrostatic electret processing technology combined with the use of products in micro straight High filtration efficiency. low resistance and long filtration efficiency decay period were observed between rl um-3um. Special advantages have been used by many domestic air filtration industry organizations. Our technology production team can customize all kinds of melt jet nonwovens for domestic customers, the product weight from 10-80 grams Different products are divided into masks for non-oily and oily filter melting spray purifier fresh air ventilation equipment Standby melting spray, filtration efficiency can reach 95%+, 99%+ can be used in air purifier5, vehicles air conditioning filters.HVAC masks and other fields. The biggest features of molten spray material products are long-term and low resistance.

Product Parameter

Low Resistance And High-Efficiency Molten Jet Material For Air Cleaner

| PRODUCT MODEL | ART-FRB-P85% | EUROPEAN STANDARD | H11-95 | |

| ITEM | UNIT | QUALITY REQUIREMENT | TEST AVERAGE | TESTING INSTRUMENT |

| MATERIAL | PP POLYMER MATERIAL | |||

| SQUARE METER MASS SINGLE WEIGHT | g/㎡ | 85 | 85±10 | GRAM INSTRUMENT |

| THICKNESS | MM | 0.55 | 0.55±0.05 | THICKNESS GAUGE |

| EFFICIENCY | % | 95 | ≥95 | TS18130

32L/MIN.D㎡ NaCl |

| RESISTANCE | Pa | 13 | ≤13 | |

| BREADTH | MM | MAX | 1470±2 | STEEL RULE |

| HS Code | 5603949000 | |||

Low Resistance And High-Efficiency Molten Jet Material for masks KN95

| PRODUCT MODEL | ART-FRB-A01 | CHINA STANDARD | KN95 | |

| ITEM | UNIT | QUALITY REQUIREMENT | TEST AVERAGE | TESTING INSTRUMENT |

| MATERIAL | PP POLYMER MATERIAL | |||

| SQUARE METER MASS SINGLE WEIGHT | g/㎡ | 25 | 25±0.1 | GRAM INSTRUMENT |

| THICKNESS | MM | 0.15 | 0.15±0.01 | THICKNESS GAUGE |

| THICKNESS GAUGE | % | 95 | ≥95 | TS18130

85L/min.NaCl (Double) |

| RESISTANCE | Pa | 90 | ≤90 | |

| HS Code | 5603949000 | |||

Low Resistance And High-Efficiency Molten Jet Material for masks FFP2

| PRODUCT MODEL | ART-FRB-A01 | CHINA STANDARD | FFP2 | |

| ITEM | UNIT | QUALITY REQUIREMENT |

TEST AVERAGE |

TESTING INSTRUMENTS |

| MATERIAL | PP POLYMER MATERIAL | |||

| SQUARE METER MASS SINGLE WEIGHT | g/㎡ | 40 | 40±0.1 | GRAM INSTRUMENT |

| THICKNESS | MM | 0.15 | 0.15±0.01 | THICKNESS GAUGE |

| THICKNESS GAUGE | % | 95 | ≥95 | TS18130

85L/min.NaCl (Single) |

| RESISTANCE | Pa | 110 | ≤110 | |

| HS Code | 5603949000 | |||

Product Pictures

FAQ

A: No, according to customer needs.

A: The professional QC team will control the quality of the goods during all mass production, or if you wish, you can arrange a third-party inspection service. We will provide bulk samples for evaluation before shipment.

A: The sample is free, but the freight is payable. Please contact us in advance if you need samples. You can prepay shipping charges via PayPal or Western Union, and we will send samples as soon as we receive your shipping charges. Or you can provide your courier (DHL, TNT, etc.) account to us for pickup.

A: We can provide customers with full supervision of the procurement process and deliver the most satisfactory goods to them.

Accept delivery terms: FOB, CFR, CIF, EXW, CIP, DDP, express; Accept payment currencies: US dollars, Euros.

A: Yes, we do. We are a professional company in livestock farm products. We have a professional and strict quality control, we must provide you the best service for your need. Our product service department will keep in touch with customers and reply at any time.

Yes, we accept ordering samples to check quality. And mixing samples is acceptable.

A: For preparing samples, depending on the number of samples and process requirements, our preparation time is 1-7 days. International express delivery time is 3-7 days.

Related products

-

Air Filtration Disinfection Of Raw Materials

PTFE Nano-Pore Size Air Filter Film

-

Air filtration Disinfection System Material And Products

Nanofiber Electrostatic Cotton Filter Material

-

Air filtration Disinfection System Material And Products

5V Sub-High Efficiency Glass Fiber Air Filter For Pig Farm

-

Air filtration Disinfection System Material And Products

4V Glass Fiber High Efficiency Dense Pleat Air Filter For Pig Sow

-

Air filtration Disinfection System Material And Products

5V Synthetic Fiber High Efficiency Air Filter For Swine

-

Air filtration Disinfection System Material And Products

High-Efficiency 4V Full Synthetic Fiber Dense Pleats Air Filter

-

Air filtration Disinfection System Material And Products

Hog Sow Pig Farm Primary Effect Bag Air Filter Element

-

Air filtration Disinfection System Material And Products

Swine Pig Farm Primary Effect Plate Air Filter Element