Product Video

Product Introduction

Product Description

The main forms of bacteria and viruses in our daily life are droplets, aerosols, drinking water sources, animals, plants, etc. Microorganisms such as bacteria and viruses exist in various forms, with a wide range of existence and strong transmission ability. Endanger human health, cause national economic losses, and cause social unrest. Bacteria and viruses have a wide range of hazards and long-term damage, and effective measures need to be taken to prevent and control them. Blocking the spread of bacteria and viruses If protective non-woven fabrics are used, the network structure of the material itself is used to intercept bacteria and viruses, which may easily lead to cross-infection and secondary pollution during use. Therefore, it is very important to develop efficient and safe bactericidal and virus-killing materials. Our R&D team has jointly developed new nanofiber air purification materials, nanofiber catalytic aldehyde removal materials, and other world-leading nano-new materials. The use of free radical active oxygen sterilization and virus-killing technology. Bacteria and viruses are in contact with free-radical active oxygen materials, and active oxygen is combined with bacterial protein sulfur groups and viral protein shells to oxidize, and bacterial protein sulfur groups and viral protein shells are oxidized and their structures are destroyed. This is a material that can both filter and kill viruses. Sterilize/kill virus/filter PM2.5 and other properties in one step. The free radical type active oxygen material has the advantages of broad-spectrum sterilization, fast killing speed, and high killing efficiency, and can effectively kill Escherichia coli, Salmonella, Vibrio cholera, Shigella, influenza virus, poliovirus, Virus, norovirus, helical virus, Campylobacter jejuni, Enterococcus, Pseudomonas, Klebsiella, and other bacteria and viruses, the killing efficiency is as high as 99.99%.

Its application value is mainly used in air filtration products. It is used in the preparation of air purification filter element products, which can effectively intercept and kill bacteria and viruses in the air while purifying the air.

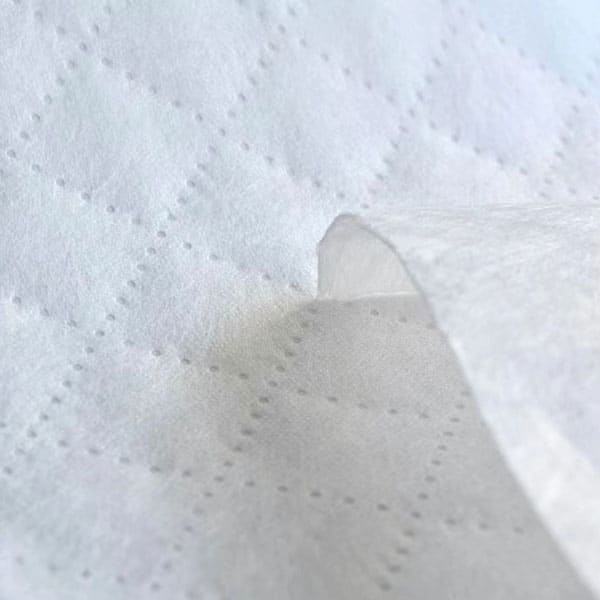

Nano-fiber electrostatic cotton filter material products using the latest electrostatic Spinning technology combining nanofibers with electrostatic electret technology, Endows the material with extremely high surface charge and charge stability. At the same time, It has higher physical interception efficiency there fore the process of using is more secure.

At present, woven fabric, knitted fabric, and nonwoven are widely used as fiber filter materials. In comparison with these traditional fiber filtration materials, has high specific surface area porosity and permeability, which makes it easier to absorb the separation of small particles, and can be used as a variety of high precision, high-performance filtering materials, with wide application prospect.

Nanofiber air purification materials are mainly divided into Nanofiber Electrostatic cotton filter material. Low resistance and high-efficiency molten jet material. Nanofiber Industrial filter paper. Red stone manganese zinc matt catalytic dialdehydes sterilization materials. Low resistance and high-efficiency molten jet material.

This nanofiber electrostatic cotton filter material can be used in industrial workshop dust removal heating ventilation and air conditioning(HVAV), Animal husbandry cleaning, etc. Our air filtration products in animal husbandry hog farm, bag type air filtration, plate type air filtration, 4V sub-HEPA air filtration, and 5V HEPA air filtration. We also develop and produce nanopore size air filtration membranes.

Product Feature

- With the minimum filtering efficiency guarantee, to avoid the efficiency of large attenuation.

- Ultra-low resistance, more energy saving.

- Stable and efficient purification efficiency more assured use.

- Super high physical interception efficiency, safer to use.

- Can be used in industrial workshop dust removal heating ventilation and air conditioning(HVAV), Animal husbandry clean plant, etc.

Product Parameter

| Product model | ART-Nano-Tech H10 | ||

| TEST PROTECT | PERFORMANCEINDICATORS | UNIT | TEST STANDARD |

| WEIGHT | 80±5 | g/m² | GB/T4669 |

| THE THICKNESS | 0.8.±0.1 | mm | GB/T3820 |

| STIFFNESS | 190±10 | mg | GB/T22364-2008 |

| THE INITIAL EFFICIENCY | 95~98

|

% | EN779-2012

TSI8130 32Lmin 0.3umNaC1

|

| THE LOWEST EFFICIENCY | 85 | ||

| RESISTANCE | <40 | Pa | |

| TENSILE STRENGTH | <100 | N/5cm | ISO9073-2012 |

| HEAT RESISTANCE | 130 | ℃ | / |

| Product model | ART-Nano-Tech H11 | ||

| TEST PROTECT | PERFORMANCEINDICATORS | UNIT | TEST STANDARD |

| WEIGHT | 85±5 | g/m² | GB/T4669 |

| THE THICKNESS | 0.9±0.1 | mm | GB/T3820 |

| STIFFNESS | 190±10 | mg | GB/T22364-2008 |

| THE INITIAL EFFICIENCY | 97-99 | % | EN779-2012

TSI8130 32Lmin 0.3umNaC1

|

| THE LOWEST EFFICIENCY | 95 | % | |

| RESISTANCE | <65 | Pa | |

| TENSILE STRENGTH | <100 | N/5cm | ISO9073-2012 |

| HEAT RESISTANCE | 130 | ℃ | / |

| Product model | ART-Nano-Tech H12 | ||

| TEST PROTECT | PERFORMANCEINDICATORS | UNIT | TEST STANDARD |

| WEIGHT | 88±5 | g/m² | GB/T4669 |

| THE THICKNESS | 1.0±0.1 | mm | GB/T3820 |

| STIFFNESS | 190±10 | mg | GB/T22364-2008 |

| THE INITIAL EFFICIENCY | 99.5~99.99 | % | EN779-2012

TSI8130 32Lmin 0.3umNaC1

|

| THE LOWEST EFFICIENCY | 95.5 | % | |

| RESISTANCE | <150 | Pa | |

| TENSILE STRENGTH | <100 | N/5cm | ISO9073-2012 |

| HEAT RESISTANCE | 130 | ℃ | / |

| Product model | ART-Nano-Tech H13 | ||

| TEST PROJECT | PERFORMANCEINDICATORS | UNIT | TEST STANDARD |

| WEIGHT | 90±5 | g/m² | GB/T4669 |

| THE THICKNESS | 1.1±0.1 | mm | GB/T3820 |

| STIFFNESS | 190±10 | mg | GB/T22364-2008 |

| THE INITIAL EFFICIENCY | 99.99 | % | EN779-2012

TSI8130 32Lmin 0.3umNaC1

|

| THE LOWEST EFFICIENCY | 99.97 | % | |

| RESISTANCE | <200 | Pa | |

| TENSILE STRENGTH | <100 | N/5cm | ISO9073-2012 |

| HEAT RESISTANCE | 130 | ℃ | / |

(ONLY TYPICAL TEST DATA OF FILTRATION MATERIALS ARE LISTED ABOVE, WHICH CAN BE USED ASA REFERENCE FOR COMPREHENSIVE PROPERTIES OF MATERIALS.

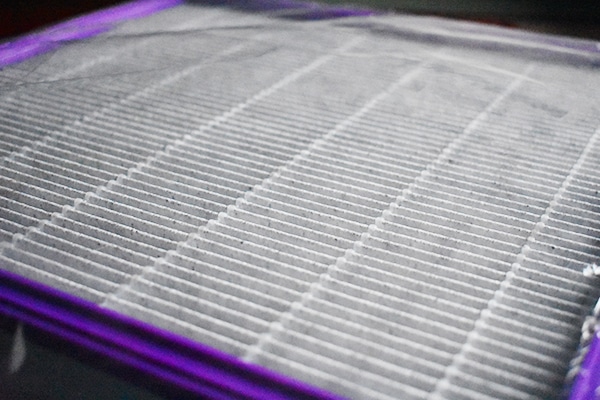

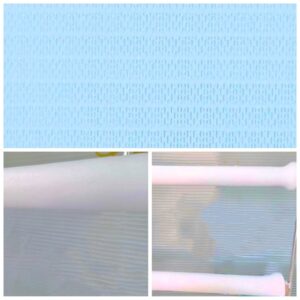

Detail Pictures

FAQ

A: No, according to customer needs.

A: The professional QC team will control the quality of the goods during all mass production, or if you wish, you can arrange a third-party inspection service. We will provide bulk samples for evaluation before shipment.

A: The sample is free, but the freight is payable. Please contact us in advance if you need samples. You can prepay shipping charges via PayPal or Western Union, and we will send samples as soon as we receive your shipping charges. Or you can provide your courier (DHL, TNT, etc.) account to us for pickup.

A: We can provide customers with full supervision of the procurement process and deliver the most satisfactory goods to them.

Accept delivery terms: FOB, CFR, CIF, EXW, CIP, DDP, express; Accept payment currencies: US dollars, Euros.

A: Yes, we do. We are a professional company in livestock farm products. We have a professional and strict quality control, we must provide you the best service for your need. Our product service department will keep in touch with customers and reply at any time.

Yes, we accept ordering samples to check quality. And mixing samples is acceptable.

A: For preparing samples, depending on the number of samples and process requirements, our preparation time is 1-7 days. International express delivery time is 3-7 days.

Related products

-

Air Filtration Disinfection Of Raw Materials

PTFE Nano-Pore Size Air Filter Film

-

Air filtration Disinfection System Material And Products

Low Resistance And High Efficiency Molten Jet Material

-

Air filtration Disinfection System Material And Products

5V Sub-High Efficiency Glass Fiber Air Filter For Pig Farm

-

Air filtration Disinfection System Material And Products

4V Glass Fiber High Efficiency Dense Pleat Air Filter For Pig Sow

-

Air filtration Disinfection System Material And Products

5V Synthetic Fiber High Efficiency Air Filter For Swine

-

Air filtration Disinfection System Material And Products

High-Efficiency 4V Full Synthetic Fiber Dense Pleats Air Filter

-

Air filtration Disinfection System Material And Products

Hog Sow Pig Farm Primary Effect Bag Air Filter Element

-

Air filtration Disinfection System Material And Products

Swine Pig Farm Primary Effect Plate Air Filter Element