Product Video

Product Introduction

Product Description

Air pollutants in swine/hog/pig farms mainly include ammonia, hydrogen sulfide, dust, and volatile organic compounds. The air quality of pig farms not only affects the health of pigs but also the staff of pig farms. With the intensive and high-speed development of global pig farming, air pollution in pig farms has become a prominent problem that restricts the healthy development of pig farming. Therefore, the control of air quality in pig barns has been paid attention by the international community.

A healthy, quality air environment in the barn is essential for raising and delivering healthy swine and piglets, as the absence of quality air filtration can lead to the spread of pathogens and viruses, especially PRRS (porcine reproductive and respiratory syndrome virus), which can significantly impact your herd, productivity, and operating costs. The common viruses and viral diameters of swine diseases are as follows:

Swine influenza disease 0.08-0.12μm

Blue ear virus (PRRSV) 0.05-0.065μm

Swine fever virus (CSFV) 0.04-0.05μm

Pseudorabies virus (PRV) 0.15-0.18μm

Foot-and-mouth disease virus (FMDV) 0.022-0.03μm

Porcine asthma virus (MHYO) 0.3-0.9μm.

Some international institutions have done a lot of experiments to show that air filters above medium efficiency have an obvious effect on the blue ear and wheezing virus which pigs are susceptible to, and these viruses are generally spread by air, especially in an unclean environment. Some of the pig farms with illnesses have not reoccurred blue ear disease in more than three years after the air filtration system was modified. Which filters should be used in pig/swine farms? General the following three kinds of filters: Primary air filter. Medium efficiency air filter. High efficiency or called sub-high efficiency filters. Through the combination of three kinds of filter filtration, it can effectively filter the disease and epidemic in the air, greatly reduce the risk of hog infection and epidemic, reduce the cost of pig farming for farmers, and solve the more important problem of pig/swine farm air epidemic prevention in pig farms.

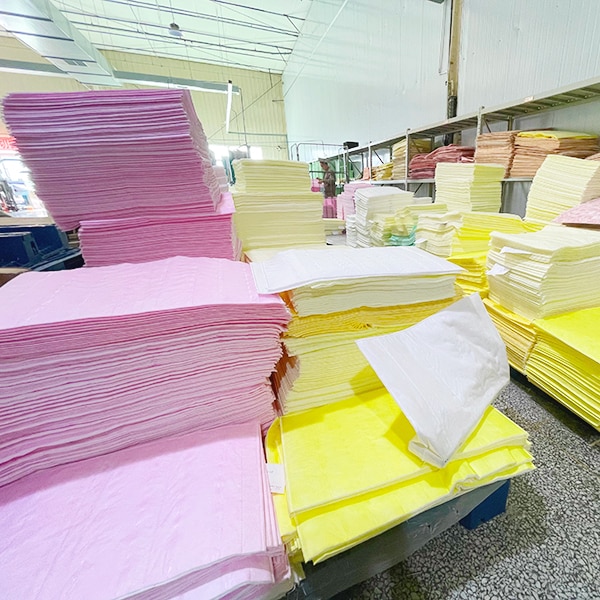

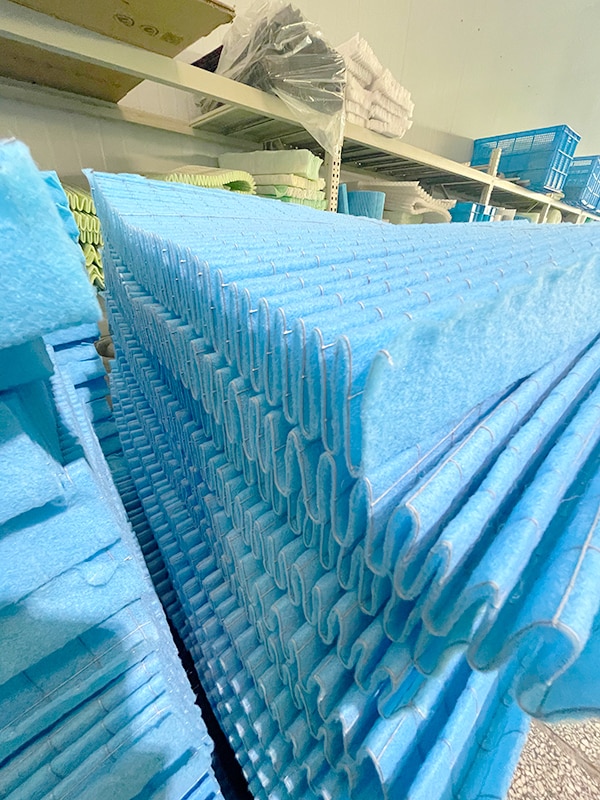

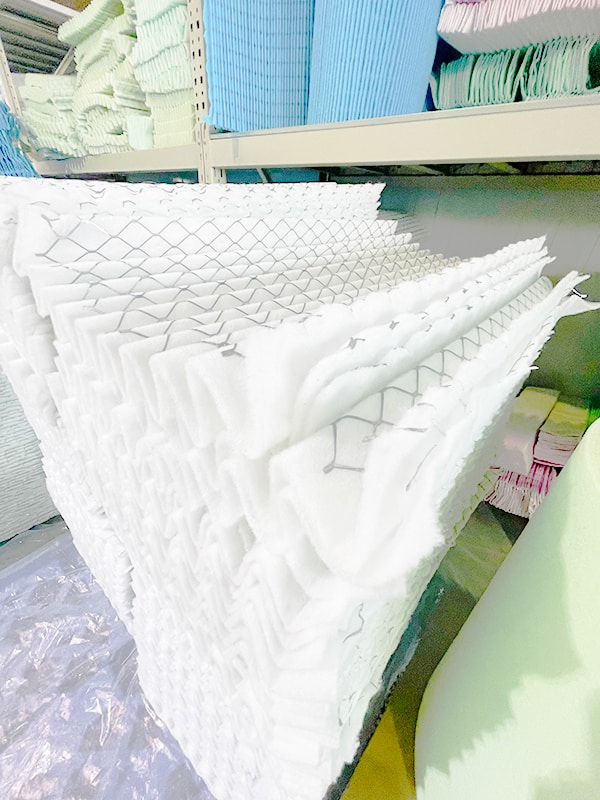

Our factory has nearly 40 years of professional air filtration research and development experience, and has long-term and stable cooperation with many large companies! Our factory develops and produces raw materials for air filtration wool and finished air filtration cartridges. Air filtration raw materials are mainly low resistance and high-efficiency molten jet materials, nanofiber electrostatic cotton filter material, PTFE nano-pore size air filter film, and glass fiber filter material. The air filtration cartridges used in pig farms in the livestock industry are primary-effect plate cartridges, medium-effect bag cartridges, sub-efficient 4V with synthetic fiber, sub-efficient 4V with glass fiber, and sub-efficient 5V with synthetic fiber, sub-efficient 5V with glass fiber.

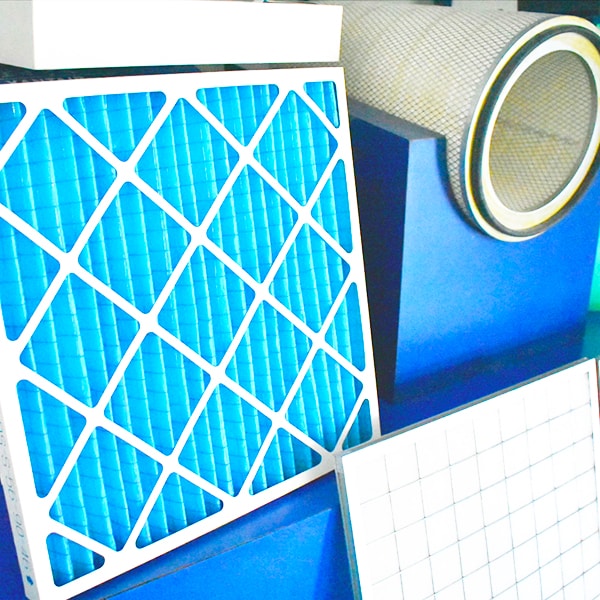

Here we introduce you to the primary plate air filter cartridge.

Product Feature

- Resistant to moisture, humidity, and corrosion can adapt to air filtration in various environments.

- Compound chemical fiber material, filtration efficiency reaches the international standard level, effectively blocking various diseases and stubborn swine fever virus, etc.

- Primary filter, which can filter out large particles and fibers and effectively protect the high-efficiency filter.

- The design of the filter is mainly a primary and high-efficiency air filtration cartridge, easy to install.

- It effectively purifies the indoor air environment of pig farms, improves the body immunity and breeding ability of pigs, and greatly reduces the mortality of piglets.

Product Parameter

HS Code: 8421399090

Product Model: ART-PAF6608 G4

Product Size: 59.2*59.2*46 cm

International Standard: MERV8

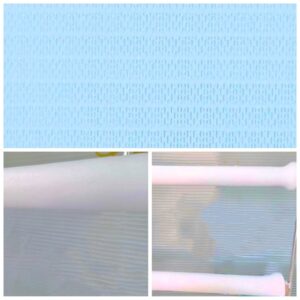

Product Material: Wet-resistant white card paper\Brown card paper frame\Non-woven chemical fiber filter material.

Performance Feature: Low impedance\handiness\versatile.

| Product model | Initial Resistance(Pa)

|

Rated airflow(m³/h) | Initial Resistance(Pa)

|

Rated airflow(m³/h) | Initial Resistance(Pa)

|

Rated airflow(m³/h) | Initial Resistance(Pa)

|

Rated airflow(m³/h) |

| ART-PAF6608 G4 | ≤60 | 3400

|

≤15 | 1000

|

≤120 | 3400

|

≤30 | 1000

|

||||

Filter air volume and resistance comparison table:

| m³/h Air Flow m³/h | 500 | 1000 | 1500 | 2000 | 2500 |

| (±5%) Initial Resistance Pa (±5%)

|

5 | 10 | 18 | 26 | 35 |

| m³/h Air Flow m³/h | 3000 | 3400 | 4000 | 4500 | 5000 |

| Pa (±5%) Initial Resistance Pa (±5%) | 45 | 56 | 75 | 95 | 118 |

Note: The units of resistance (pressure) used are as follows: 1 inch (Inches)=249Pa, 1 mm (mm)=9.8Pa

Several common flow (wind) unit conversion: 1 cubic foot/minute (CFM)=1.7m³/h, 1 cubic meter/minute (CMM)= 60m³/h.

Detail Pictures

FAQ

A: No, according to customer needs.

A: The professional QC team will control the quality of the goods during all mass production, or if you wish, you can arrange a third-party inspection service. We will provide bulk samples for evaluation before shipment.

A: The sample is free, but the freight is payable. Please contact us in advance if you need samples. You can prepay shipping charges via PayPal or Western Union, and we will send samples as soon as we receive your shipping charges. Or you can provide your courier (DHL, TNT, etc.) account to us for pickup.

A: We can provide customers with full supervision of the procurement process and deliver the most satisfactory goods to them.

Accept delivery terms: FOB, CFR, CIF, EXW, CIP, DDP, express; Accept payment currencies: US dollars, Euros.

A: Yes, we do. We are a professional company in livestock farm products. We have a professional and strict quality control, we must provide you the best service for your need. Our product service department will keep in touch with customers and reply at any time.

Yes, we accept ordering samples to check quality. And mixing samples is acceptable.

A: For preparing samples, depending on the number of samples and process requirements, our preparation time is 1-7 days. International express delivery time is 3-7 days.

Related products

-

Single Stomach Animal Products

Piglets Tooth Pliers

-

Single Stomach Animal Products

Animal Ear Notchers

-

Air Filtration Disinfection Of Raw Materials

PTFE Nano-Pore Size Air Filter Film

-

Air filtration Disinfection System Material And Products

4V Glass Fiber High Efficiency Dense Pleat Air Filter For Pig Sow

-

Single Stomach Animal Steel and Machinery Products

Sow Farrowing Pens Sow Positioning Bar

-

Single Stomach Animal Steel and Machinery Products

Pig Farm Farrowing Crates Pig Obstetric Table

-

Air filtration Disinfection System Material And Products

Hog Sow Pig Farm Primary Effect Bag Air Filter Element

-

Ruminant Farm Management Products

Cattle Cow Farm Split Ear Tag